Our Patented Processes

Our Patented Processes

The World’s Only Continuous Process for Mesophase Pitch Production

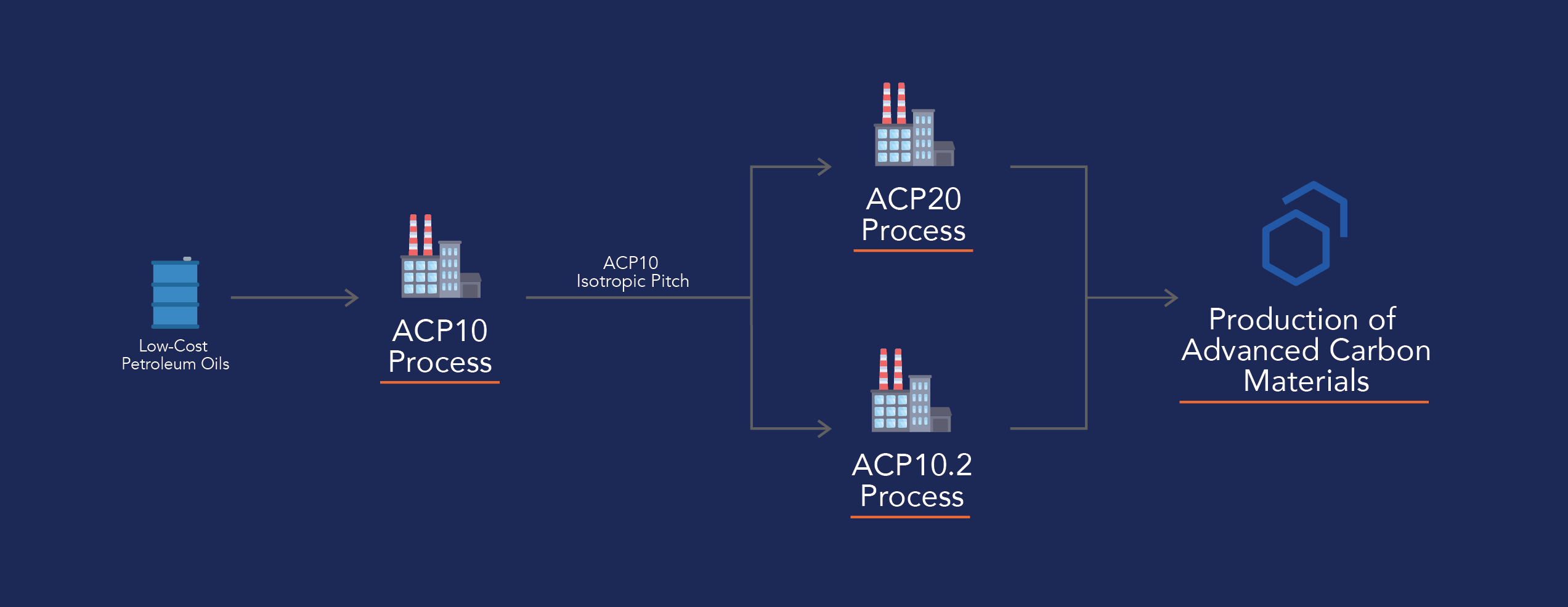

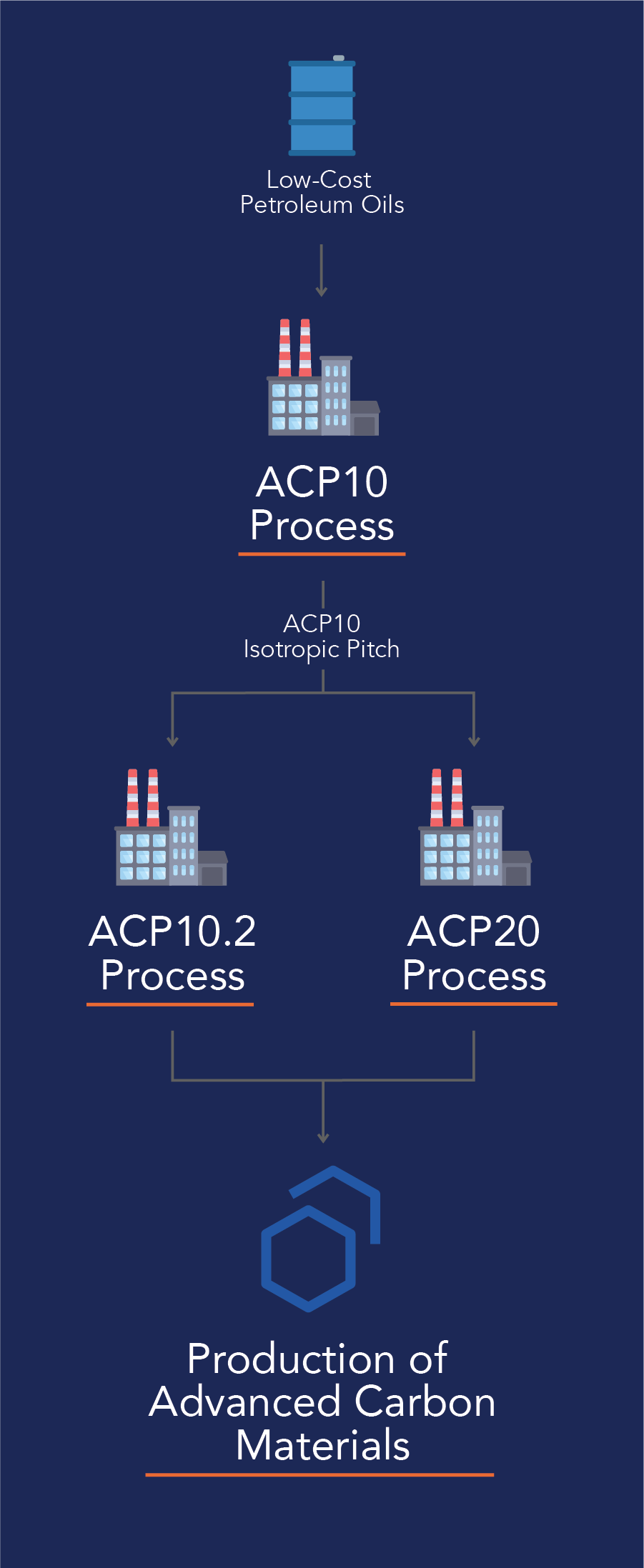

At ACP Technologies (ACPT), we’ve pioneered a groundbreaking method for continuously converting low-cost petroleum oils into high-quality mesophase pitch. Our team has introduced the first-ever continuous process capable of producing low-cost mesophase pitch within minutes, surpassing traditional processes for efficiency and production time. Unlike conventional methods, which can take hours, our patented processes enable us to rapidly and economically deliver high-quality pitch materials to our customers.

Enabling a U.S.-Made Supply Chain for Critical Materials

ACPT serves as a domestic supplier of the precursor pitch used in the production of several critical materials, including carbon fiber, battery-grade graphite, and carbon-carbon composites. Through our innovative processes, we facilitate the production of these vital materials at a significantly reduced cost compared to current methods.

The Isotropic Pitch Process (ACP10)

The process starts with low-cost aromatic petroleum oils that are usually burned as low-grade fuels. After filtering the oils to remove any solid impurities, we feed them into our Isotropic Pitch Process, where the aromatics are polymerized into isotropic pitch in our continuous process. Our conversion to isotropic pitch takes only a few minutes, instead of the hours it takes in conventional processes.

Isotropic pitch consists of large aromatic molecules that are solid at room temperature. Our ACP10.2 process allows us to vary the softening point of our isotropic pitch to suit its intended use. Typically, this ranges from 90°C to 220C° with micro-carbon values (MCR) from 50 wt.% to 80 wt.%. The finished isotropic pitch is then ready to be utilized in a variety of applications.

Common applications of isotropic pitch include:

- Precursor for making mesophase pitch

- Carbon-carbon composites

- Coatings on graphitic microbeads for lithium-ion batteries

- Anodes for the aluminum industry

- Electric arc furnace (EAF) electrodes for the steel industry

- Carbon fiber

- Driveway sealers

- Coatings and enamels

- Refractories

The Mesophase Pitch Process (ACP20)

Isotropic pitch has many uses, but it can also be used as the feedstock for our Mesophase Pitch Process. In this process, the isotropic pitch molecules are converted into mesophase pitch, again in a continuous process that completes the conversion in only a few minutes. Mesophase pitch is a semi-crystalline form of isotropic pitch that can be used to make many different high-value carbon-based materials.

Common applications of mesophase pitch include:

- Graphitic microbeads for lithium-ion batteries

- Carbon fiber

- Carbon-carbon composites

- Carbon-carbon brakes and friction materials

- Carbon and graphite industrial materials and parts

- Graphitic foam

- Fuel cells

Sustainable and Cost-Effective

The ACPT processes reflect a commitment to sustainability by efficiently utilizing resources and reducing production time, leading to cost savings for our customers. In addition, ACPT’s pitch process sequesters carbon that would otherwise be burned in valuable solid products; thereby reducing the amount of carbon dioxide released into the atmosphere.

Testimonials

Take the Next Step Today

Reach out to us to discuss the potential for collaboration and explore how together we can capitalize on the possibilities.